I chose the following manufacturing parameters. After I made the QR code, in a third-party editor I made a horizontal reflection so that it was displayed correctly on the board itself. This is what the bottom layer looks like in the editor.Īn important point. For the QR code, I have selected the "Bottom Label" layer.

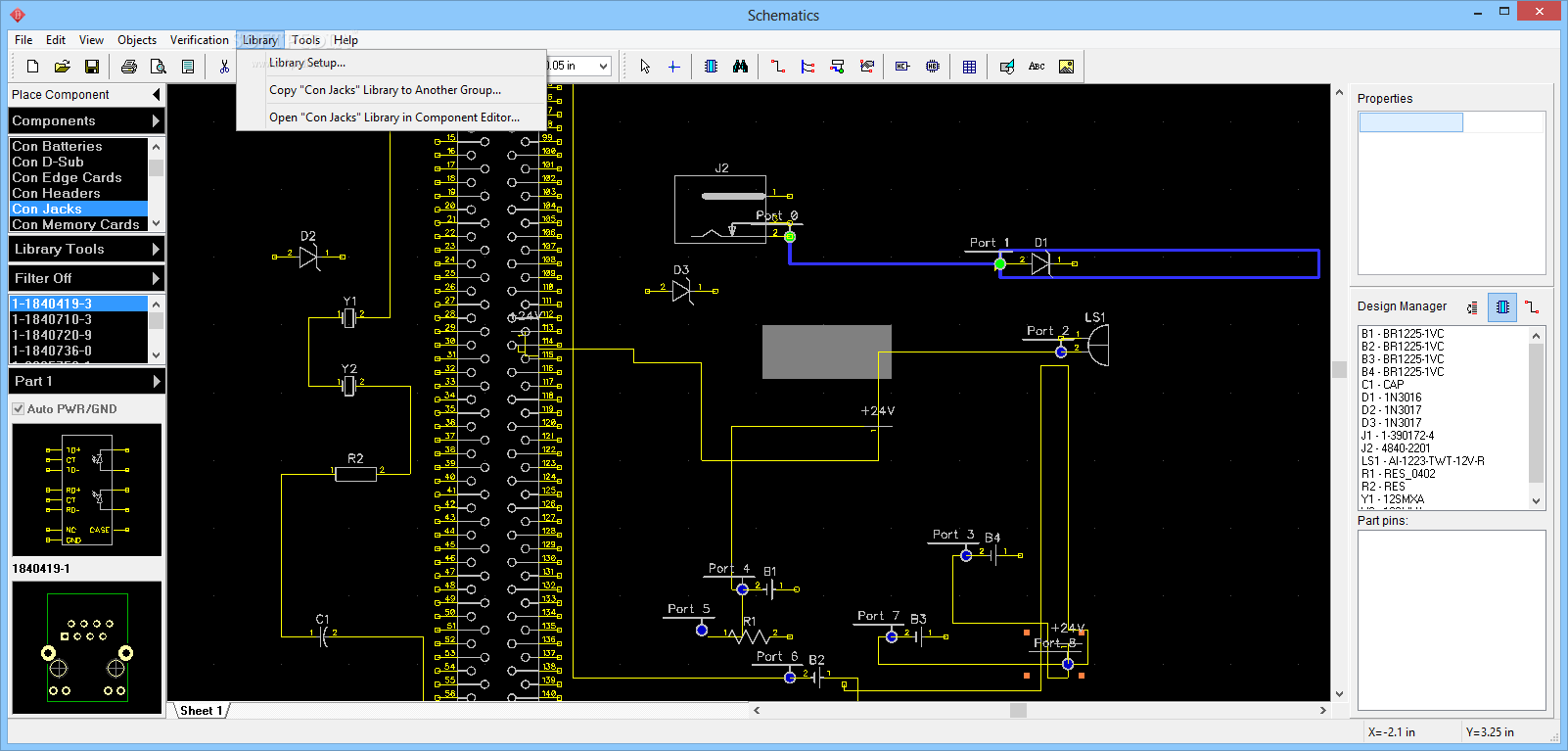

The "Image" tool allows you to immediately convert any image into a vector and give it any layer on the board. The Dip Trace functionality also helped in this. There I placed a QR code for writing to the phone of the contact of our company. But we are left with an empty bottom side of the board. To do this, I copied the text, made it a "Top Mask" layer and positioned it exactly above the text in the copper layer. As well as the contact pads of the components. I wanted it on the contrary, plus to this, that it went through the tinning process, to give it a silver color. The layer has selected "Cooper" and "Top".īut, if we leave everything like that, the text will be covered with a protective solder mask.

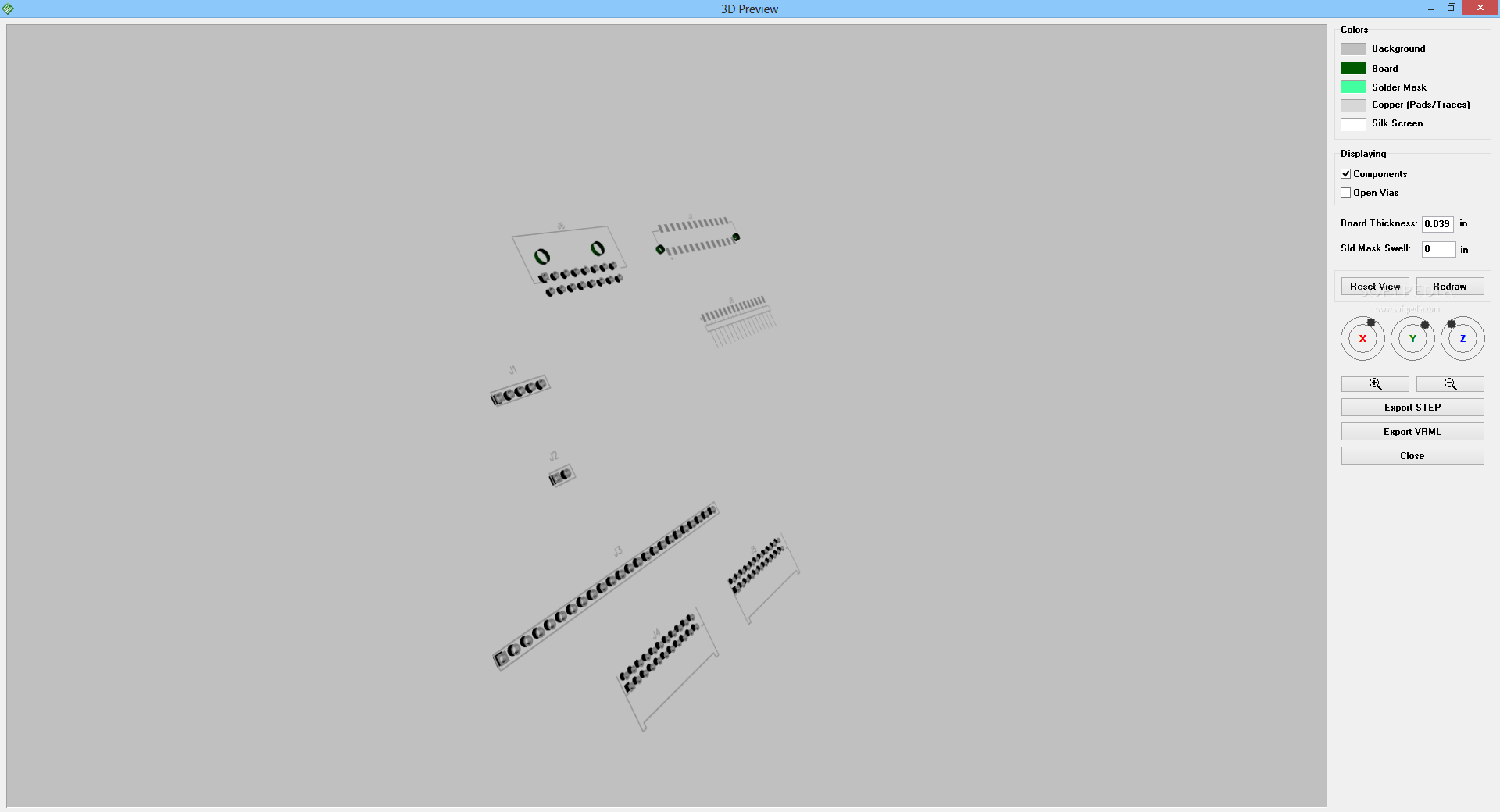

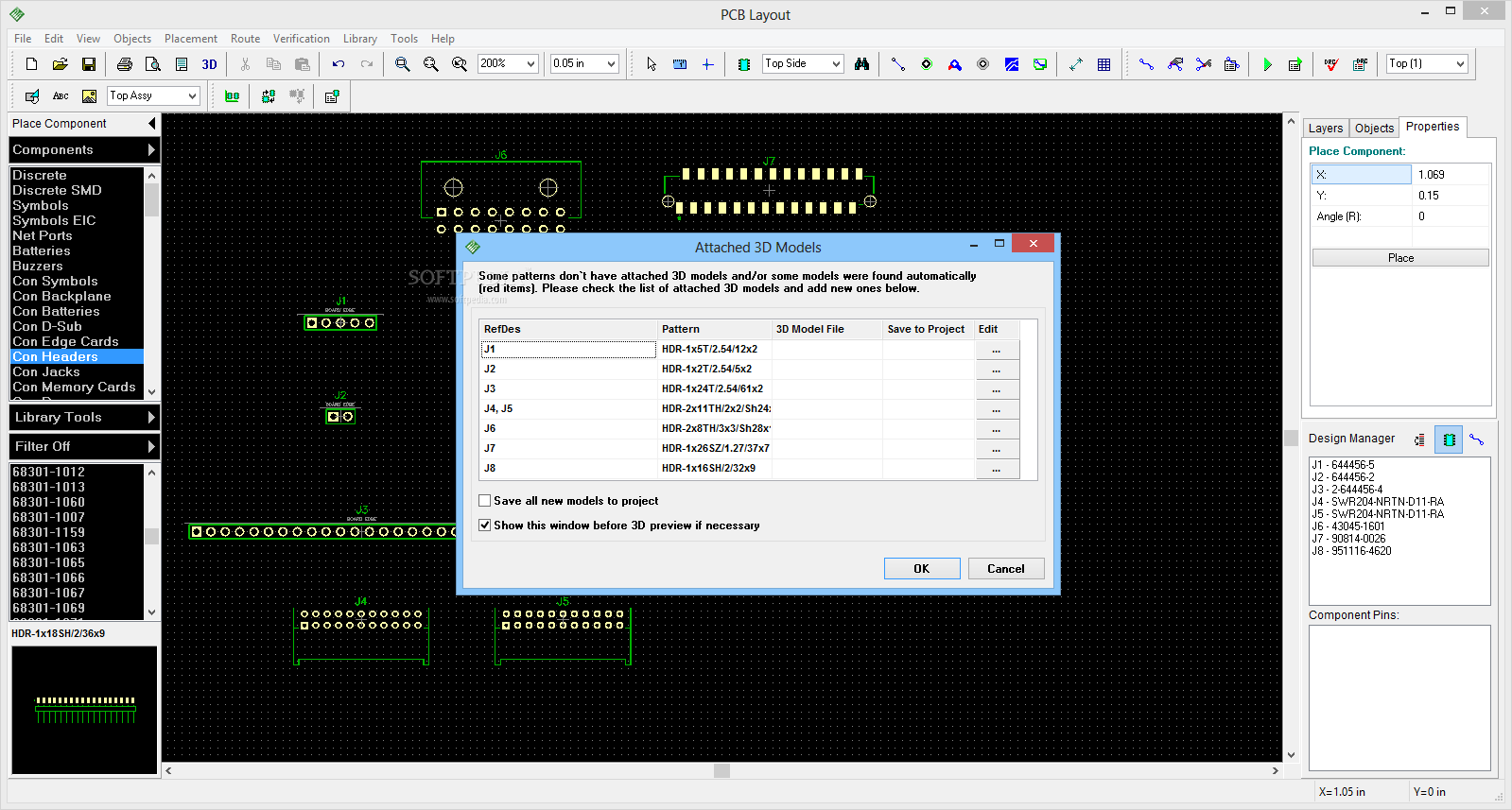

Then, using the "Text" tool, I placed my contacts. You can't do without them, otherwise what kind of electronics is this) I even used autorouting to make the tracks appear. The order does not matter, here I do it based on the design and the required free space. Enter the dimensions and radius of the corners we need, and the shape is ready. In general, the latest version of Dip Trace has a handy tool for drawing board borders. This is the exact size of a plastic bank card. I chose a rectangle with rounded edges, 84.6 * 53.98 mm. I wanted all the text to be done on a copper layer and not be covered with a protective mask. I removed some unnecessary elements such as large connectors and everything that could interfere with the location of the contact information. I opened the board editor in Dip Trace, found a standard example of a printed circuit board that comes with the software. Just like a real board, I was not going to solder anything. I needed the business card to contain space for any electronic components, tracks, holes, etc. I don't even know how relevant they are, but an unusual approach to the issue will definitely not be left without attention. I decided to make myself a business card in the form of a printed circuit board. I had been planning to make myself a business card for a long time, but still could not decide on the design.

0 kommentar(er)

0 kommentar(er)